Every project reaches a point in which things start to get hard, trouble arises and you start to worry whether you will make it on time or not. The last five days have been just like that. But despite the setbacks, we have to find new ways to overcome, be creative and use the opportunity for the better. And I think we have done just that. Here is a recap:

Wednesday 20th

Machines (PCs) with Vista are hard to boot in windows XP but that’s nothing compared to trying to get Linux to run on a new machine…. no drivers for new boards.

Wednesday I brought the computer that I bought for the machine into the shop for the software team to get started. I was supposed to give them an XP box and the machine came with Vista. Well, I could not install XP with my DVD copy - I needed a boot copy. After meeting with them we decided simply to wipe the machine and boot it in Linux. They would take care of this. And so they started the process only to find out that Linux still did not support some of the boards on the this brand new machine. We needed an older machine. Hans agreed to lend us one from his lab in the meantime. We will build on that and test while we figure out who should build our own machine out of older parts. Actually I will ask Tim at headquarters to see if he has something laying around. Then there are problems with the control board; even though it says specifically that it supports Linux EMC (that’s a flavor of our CNC Linux), that board is not updating its firmware. The group got on the user group and forum to try and find a fix. Today I should know if they got any where but overall the difficulty of configuring hardware to run with Linux may be something that will seriously discourage users from engaging in building their own machines. I am sure that we can incorporate difficult component design and assembly strategies and people will not complain. After all this is what they do for a living but getting on the Linux board to try and get their specific hardware to run it is other story best left to computer-savvy individuals. Hopefully we can standardize the procedure enough for it not to be a barrier to entry.

Z redesign started again

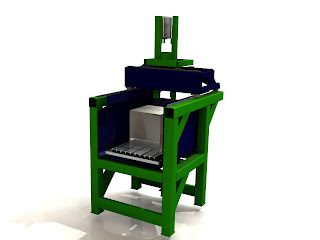

Ok, our previous design was proving too difficult to align and true. It seamed elegant and efficient on the computer, but after working with the material on the y axis, I realized that it was going to be impossible to true (align faces at 90 decrees to each other). So I decided to stir the design to a more traditional approach. I told the team that many times - you think you are being innovative and as you refine your design you end up looking very similar to what is out there already. This happens for a reason - a 50-year-old machine out there that’s working is in parts because of its good design, tried and tested. So we are back to tried and tested.

It’s Wednesday afternoon and the materials at hand are steel plate and 5” perforated bar. Camilo and I started working with this to come up with a design that can be cut on Thursday in the plasma cutter and welded on Friday. However, that computer running the CNC plasma went down on Thursday morning, we found a bug in the design that we corrected on Friday, delaying the tool path programming. And to make matters worse, around mid night on Friday I found another major bug. I was flying out to Boston on Saturday morning and had no easy way to get in touch with Juan, his home phone number was written on the shop’s white board and I had to be at the airport at 7:30. So once I checked in I woke up Pedro to ask him to try and find Juan and stop the cutting or try to correct the problem. I just got word today that indeed it got stopped. I should call them right now before getting on the flight to Medellin.

Y-axis needs to be redesigned

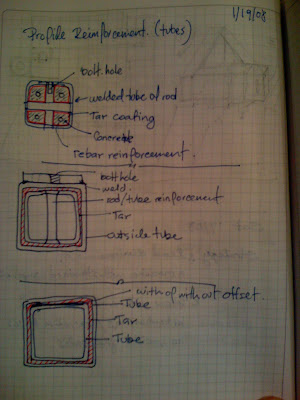

Remember that long blog entry about using the inserts embedded in concrete? Well that idea was not going to work. Why? Simple - they don’t have enough interference with the concrete. And what determines the interference factor with concrete? The average size of the grains of sand. You need a few of them to fit in-between interference elements. With the inserts I got you could barely fit one grain. So those would not work. Also as we thought more and more about the idea that if we machined custom inserts, which was still a possibility, we still had major leveling and alignment problems. The inserts need to be very perpendicular to the rail, other wise they will induce uneven forces. This was not apparent until we had aligned one side of the beam with inserts. So off came the inserts. We needed a better solution, one that would take care of the threading requirements and the flatness. We decided to weld on a half inch piece of plate on top of the beam. The only problem was that we would need to machine it to make it flat, other than that it would take care of all the problems and make for a very nice surface for mounting and re-mounting as needed.

Now this story has a happy ending, Esteban invited a friend over (I forget his name) and he brought him in because in the past they have worked together and he has proven very valuable with innovative solutions. Esteban explained to him the problem at hand, that we need to plane the surface without using a larger machine and that it had to be easy for users to reproduce. After watching us mix and fill in the structure with concrete, which I will tell you about later, he uttered an incredible idea: Use the existing Y-axis rails mounted not on top but on the side of the structure to mount a grinding tool and with gentle passes level the top surface. Now why does the idea work? Very simple - it is easy to align a rail in parallel to a surface. We had figured this out before, simply bolt the rail on with underside screws, and not tighten it down too hard. Place a laser beam on one of the railheads, project it one wall far away and run the rail back and forth. With two people, one calling out the direction of the laser displacement and a second with a soft hammer tapping the rail up and down, one should with reasonable ease ensure that the rail ends up as aligned as possible with little cost. If one wants to go crazy you can up the power, focus and distance at which the laser is projected. I will quantify this sensitivity of the setup later.

Now we have a rail that moves in the Y- axis that is as flat as needed in the x-y plane. All we need to do next is to figure out the grinding setup. I made a quick run to the a hardware store in Medellin an picked up a small vise with an x-y displacement adjustment. It cost me the equivalent of $70 USD and this weekend at home depot I picked up a 2-1/4 hp Rigid router with a 1/2in collet. The router is good from 10,000-23,000 rpm. With the proper stone we should see sparks fly. It may take some time to run and adjust the router to get a fully flat surface but this will be a very solid flat surface. And the part that I like the most about this technique is that it can be used around the machine, not only on the y but the x and z axis, as well. If this technique is mastered we can be making home made machines with high tolerance ground surfaces for rail ways for peanuts. To make sure this method is accurate I have procured a digital displacement gauge with digital output. It was pricy around $700 USD including all the cables and signal-conditioning box. Since I am pressed for time, computer plotting is essential but someone with fewer resources can accomplish the same with pen and paper and a $150 gage. I will definitely keep you posted on how this goes. Also, the rigid router is special in the sense that it seems you can mount it backward through its base with a simple modification. This will give you a nice mounting structure at the rear of the router.

Coming back to the Z-axis design

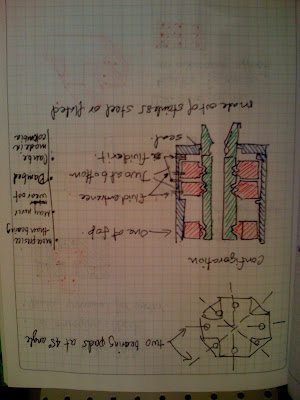

It’s Wednesday and we need to finalize the power transmission system. We need a 1:3 ratio to use the full rpm’s of the spindle 9,900 rpm. We know belts are quiet, low maintenance and relatively forgiving. We looked around for V (multiple) belts, and trapezoid (teeth) synchronous belts. After some rough sketcheas we had an idea of what would do the job. Esteban and Lina set off to buy the material for the concrete mix and visit the local belt supplier. They came back with not so good news, the supplier has V belts good for 3600 rpm, and synchronous belts were also good for 3600, were special order and cost the equivalent of $380 US. They had also asked for J-section belts, those are the ones with many small v grooves, the same type you’ll find in cars. They said they are almost impossible to find. This came as a shock to me - all I need to do was to walk to my auto parts store and order a belt for my suburban. I know it can handle the rpm’s because the Chevy small block has like an 8 inch pulley at the crank, and the alternator is about 2.5 inches and it redlines are about 5,000 rpm at the crank. It has plenty of accessory loads and runs for thousands of miles in a high temp environment., while also enduring winters and summers. I had no doubt this J-section belt will do the job. We could even use the same belt tensioner as the small block. Frustrated, I went back home that evening and went online to find this belt and pulley. After surfing through Autozone, I remember looking up the belt while building solar cars at MIT in McMaster-Carr. Indeed they had everything I needed with overnight delivery. I stayed up past 2 a.m., modeling the pulleys and configuration, weighing design options between synchronous and J-section, determining belt lengths, setup cost, pulley rations, motor positioning and coupling specifications. The most expensive setup came out to $320 USD for the J-section with twin 8-groove belts for a total of 16-groves. I couldn’t find an idle pulley for something this wide, so this is still to be designed. We may make it ourselves or we could buy two belt tensioners (for about $100UDS).

Thursday 21st

I came in early on Thursday and got Lina to start integrating the pulley design onto the Z –axis. During lunch Camilo and I continued. In the morning Camilo had also finalized the new pieces for the Y-axis so Juan, Esteban and Yesid got working on those pieces.

We also decided to play with plastic metal and resin from Devon. It was one of our original options for leveling but we had not tried it out. So we set up to do that. We found that it is quite thick and a vacuum would be needed to take out all the bubbles. It also did not level very well. The final finish was hard enough for us and after some hand filing the results where not that bad. I have a 4 lbs can on order in case we do end up using it.

We also got the Ethernet cable wired into the shop space, we were not live but at least the cable was in. Gabriel was key in making this happen. He really got people moving. As of Friday we still did not have our IP address configured but we did put a wireless router in place to get all of our machines connected.

We tried to stay late on Thursday to make sure the plate section for the Y an Z got cut but Juan decided to go home and do it in the morning. I was not very happy with the decision and it was precisely the next morning that while fiddling with the drive partitions of the machine’s controlling PC that he brought the machine down. It wasn’t until a restoration image was loaded that the machine would be operational. However, this delayed that spindle all through Saturday. It ended up being as kind of a blessing in disguise. It wasn’t until midnight on Friday that I discovered another major bug in the design. I went to bed again late worried about the structural soundness of the z-axis structure. It would not be until Saturday that I would analyze this with care.

Friday went by like a blur. However we did fill in with concrete the four vertical columns of the machine. Juan Ignacio and Pedro mastered the art of preparing high strength low shrinkage cement. Yesid made a special funnel out of welded sheet metal and off we went, stuffing and shacking the machine to make the viscous concrete flow. The reason for doing it Friday was that we could leave the machine untouched for the weekend while the concrete would set. It need about 48-72 hours of cure time to avoid internal cracking.

We also spent some time working on the setup to mount and align the Y rails on the side of the machine and figure out a mounting structure for the grinding head. We took apart the head of a magnetic drill. Its nice cast base and Z slide were quite useful. We also shopped around for large level (72in type) and found none. After asking around they would have to be special ordered. I did pick up the vise mentioned earlier. The level would have to come form Home Deport state side. I was coming over on the weekend to pick up parts so it was a good time to do this.

Saturday, started out again early in the morning to catch my 9:30 flight out. Its about 45 minutes to the airport and for international they want you there at least 2 hour early so it all ads up.

I spent the MDE-MIA flight designing a casting to the Z axis. I wanted to compare weight and stiffness. I had something slighty heavier at around 200 lbs initially. Once I got to MIA and realized that because of bad weather the day before in Boston I was not going to make any standby list. I sat down for about 6 hours to await my 9pm flight to Boston. During this time I ran an FEA analysis on my initial casting design. The results were not encouraging although they were much better than welded plate steel. After a few iterations, I was getting a ~0.002inch deflection with a 400lb frontal load. I figure this not bad. It is still a lightweight part and it is not reasonable to expect precision under such load conditions. Anybody trying to get more precision will slow down the machine hence reducing the cutting force. I also let the team know to have enough MDF available to make a mockup of the spindle for casting.

Sunday was a long day, having gotten home at about 1 am, I got up early to unpack and clear out all the boxes that had arrived during the week. It really bugs Diana when our modest apartment has been taken over by boxes. This procedure is not simple. I have to check that the packing list matches the content. I have to unpack and get rid of any excessive packages. I need everything to be unpacked for TSA and especially for Colombian customs. If it seems that things are new and in original packages they could give you a hard time, arguing that you are bringing them in for resale. Then I have to recycle all the packaging and break the boxes down to 2x2 feet squares for the recycling truck to pick up. See, Cambridge has one of the country’s most sophisticated and thorough recycling programs. Some people call us the people’s republic of Cambridge but we don’t care. We are proud of our 6 different recycling classifications and that organic waste gets composted by the building for its own garden. I didn’t quite manage to finish before Diana got up but what upset me the most where the paper cuts. Two deep paper cuts while opening these damned boxes.

O well. Not everything that I ordered had arrived. UPS red had failed me! In fact things that were supposed to arrive on Friday did not, and items I ordered Friday morning with UPS red did arrive. I checked online and some stuff was due on Monday the 25th, the same day I was schedule for a 5:30 am departure to Miami. So I called American to weigh my options. A ticket change was $650 for Tuesday and even then there was still one large order on UPS ground with no due date information because McMasterr-Carr’s website was down. So after pondering my options, which included sending Diana, my brother or her sister with my own miles the following week. It turns out that it was inexpensive enough to come back the next weekend for a day. This was a good option because it allows me to find those belt tensioners and see Diana at least for a day. Plus I need the quiet time on the plane to get things like the project’s budget updated and this blog done.

I also managed to go to Home Depot, buy my levels, and some 4in drain pvc tubing to pack them in for protection. Got the router and some bits and headed home to pack. Packing also is not simple. I have to weigh what I bring. I know I am over weight but I try to keep the extra bags and weight to a minimum. Also I have to be conscious that the TSA guys don’t like what I pack - too many large metallic heavy objects, mysterious epoxies and sharp tools. I can just see them opening and rescanning things. So the packing has to allow for easy inspection, removal and repacking. The PVC worked great this time, and everything fitted very nicely in my ski bag.

Monday, 25th.

I am back on the road again. After working on the plane, I arrived in Medellin and my ski bag did not make it. Anyway I came down straight to the shop to unload. I got the good news that Linux and the PC card were working and that signals where coming out. Next step, a motor screw setup for testing. We stayed late on Monday, we figured out how we wanted to mount the y-axis rail and stayed until the pieces where tacked in place so in the morning Yesid would fully weld them. We made it home by 11:30 just enough time to catch-up with email and a shower.

Tuesday, 26th

First thing, the driver for AA picked me up and took me straight to airport to claim my delayed ski bag. Did I mention that the new rails for the Z axis where in there? Yep - SHS35’s 1000mm long. I think I mentioned this but the DIAN (Colombian customs) requires that you come in person. As I picked my bag I noticed the same DIAN officer I always see and approached her. They know me by now because of my unusual luggage in a relatively small airport. I took the time to explain to her what I was doing and what to do in the future with more industrial like machinery. It was good that I talked to her. Then back at the shop, Yesid was finishing the welding and it was time to re-level the machine. As I took the time to level the base to within 50microns per meter I realized with 4 feet left that it was going to be impossible. So the three-leg design that I had originally designed was needed. Luckily all the pieces were already cut, so Yesid got to assembling them while I carefully scraped off any imperfections form the rail bases. Some final reviews to the Z axis casting and it is off to quoting tomorrow.

Tonight we fix in place the first set of rails (y-axis). Dinner break is over – second shift is just getting started.

this is me smiling after finally assembling the Z axis with the spindle and drive pulley.

this is me smiling after finally assembling the Z axis with the spindle and drive pulley.